Ben Cheetham of Keystone Lintels provides insight into the fabric-first approach to design, and how a one-piece thermally-efficient lintel can significantly improve SAP ratings and improve the overall fabric efficiency of buildings.

Keystone Lintels

It has been identified that thermal bridging can be responsible for up to 30% of a home’s heat loss, with much of this associated to window and door surrounds. So what measures should be considered when creating thermally efficient new homes to help reduce this figure?

Decarbonising our housing stock through fabric measures built in for the life of a building is one of the most effective ways to reduce energy consumption. This fabric-first approach concentrates efforts on improving fabric U-values, reducing thermal bridging and improving airtightness. When compared to more costly renewable technologies, which have a limited lifespan and risk a significant increase in CO2 emissions from a development once they reach end of life, fabric-first is the secret to building in energy savings for the lifespan of the building. This approach will enable specifiers to meet and even exceed regulatory performance criteria, whether it is for large-scale social housing or a much smaller residential property.

Achieving a reduction in CO2 emissions is not the only consideration when designing thermally-efficient housing. Improvements in thermal comfort can have a positive impact on the wellbeing of occupants, greatly increasing their health and productivity.

The benefits are increasingly widely realised, and ongoing research continues to reinforce the significant positive impact this approach can have – economically, environmentally and socially.

Thermal bridging

When taking the fabric-first approach to design, preventing heat loss by addressing thermal bridges has become increasingly important, as research from the BRE has shown it can account for up to 30% of heat loss from buildings. A localised weak spot in the thermal envelope of a building, a thermal bridge, is where there is increased heat loss compared to the surrounding area. For example, a thermal bridge is created when a traditional steel lintel spans between the inner and outer leaf of a cavity wall, allowing heat to flow through the steel and bypass the cavity insulation to the outside environment.

A building envelope will have two types of thermal bridge: repeating thermal bridges and non-repeating thermal bridges. Repeating thermal bridges are accounted for in the calculation of a building’s U-values (U-values measure how effective a material is as an insulator). Any material that penetrates the insulation repeatedly and predictably in a heat loss element would be classed as a repeating thermal bridge. For example, this could be where timber studs bridge a layer of insulation in a wall. The increased heat loss is incorporated into the U-value calculation through bridging factors.

The remaining non-repeating thermal bridges are typically found in junctions located within the external envelope of the building and are dealt with by “Psi values” – pronounced ‘Si ’. Examples of non-repeating thermal bridges would be a steel lintel above a window or door opening. Junctions such as these are assessed using thermal modelling software and their impacts on the building’s energy performance must be calculated independently in addition to U-values.

Furthermore, it is important to note that improving fabric performance and airtightness through better detailing and on-site practices is particularly important in reducing thermal bridges on both new-build and retrofit projects.

Thermally-efficient lintel

Traditional steel lintels have become one of the more significant thermal bridges in homes due to steel having a high thermal conductivity value and because they span over long lengths in a typical build. However, a lintel design which incorporates a thermal break will outperform and be much more efficient than a standard lintel.

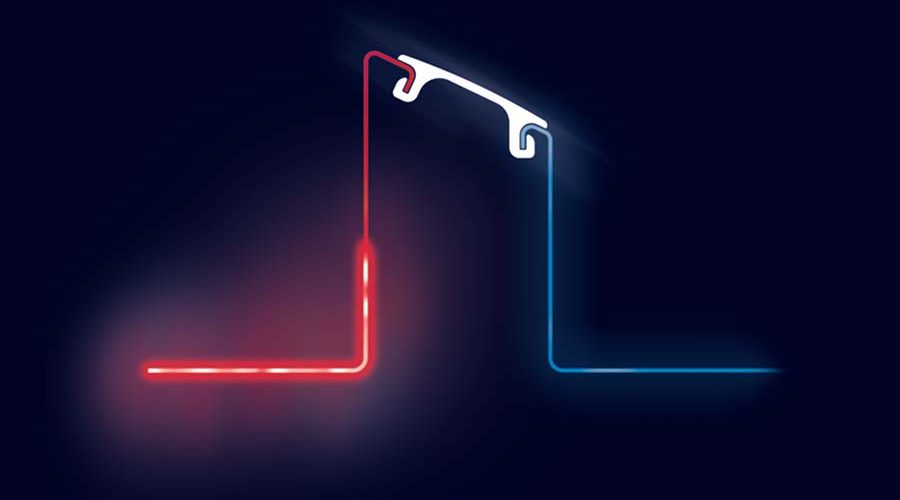

For instance, Hi-therm+ lintels use a patented combination of a polymer isolater and galvanised steel. The polymer section provides a powerful thermal break in the lintel and significantly reduces its conductivity value, with a Psi value of between 0.03 and 0.06 W/mk. As a result, Hi-therm+ Lintels are up to five times more thermally efficient and are also available in the same lengths, sizes and loading capacities as the standard range of lintels.

Adopting a fabric-first approach from the initial design stage will ensure a home continues to perform energy-efficiently throughout its lifecycle. It is however, always in the detail. If an issue such as thermal bridging is not considered from the design stage, then the overall thermal efficiency of the building will be compromised. It is why it is incredibly important to specify materials and components which deliver where others cannot – it is after all the difference between a sustainable and inefficient home.

Summary

When you consider that thermal bridges are one of the most significant sources of heat loss in buildings, paying close attention to the details and structural elements such as lintels can have a huge impact on the overall thermal performance of a building. The adoption of a fabric-first approach will ensure it continues to perform as designed both now and in the future and go some way to ensure UK homes are climate-ready.