Proof of compliance is set to be one of the major changes to Approved Document L in England next year, putting pressure on contractors to close the performance gap. But what does this mean for public sector developments, and will this change be the silver bullet? Paul Barrett, Head of Product Management at ROCKWOOL, explores what the alterations to Part L mean for the specification and installation of insulation and whether the amendments need to go further.

ROCKWOOL

A series of changes to Approved Document L (ADL) in England are due to come into force during 2022, acting as a stepping stone to the Future Homes Standard and as part of the journey to achieving net-zero carbon by 2050.

Following the publication of the consultation version of the guidance, some headline changes are known within the construction industry and, if moved into law, will have a significant impact on how we design and construct buildings for the public sector.

Born out of a need to close the gap between specified and as-built performance, one of these amendments will be greater scrutiny of build quality. In England, this will manifest itself as the introduction of Building Regulations Part L (BREL) and Buildings Regulations UK Part L (BRUKL) reports for dwellings and non-dwellings respectively.

While dwellings will require photographic evidence of compliance under the BREL report, the new guidance surrounding non-dwellings takes a different form which public sector construction stakeholders will need to be aware of.

Two BRUKL reports will be created during a building’s development, a pre-construction report which indicates planned performance and a post-construction report which shows as-built performance. The reports are generated and analysed by a specific software package which highlights inconsistencies between specified targets and built results, and produces a schedule of changes. The results must be countersigned by an energy assessor.

While stricter planned versus as-built performance checks are a good start, performance gaps may still occur, thus we need a more stringent methodology to determine as-built performance throughout a building and, in particular, properly installed insulation to ensure the required performance is achieved. To fully realise net-zero carbon by 2050, specifiers and contractors will need to do more to ensure buildings perform well into the future and key to that is the effective specification, installation and monitoring

of a robust insulation solution that provides continuity of performance.

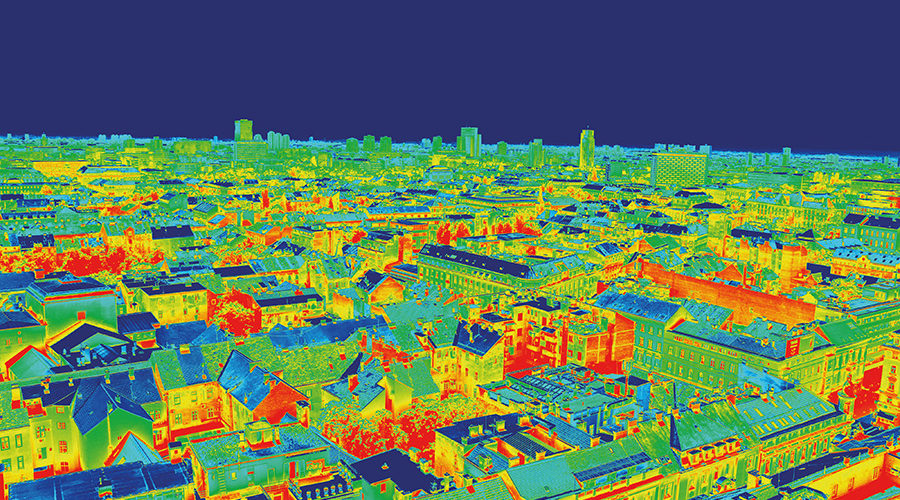

Thermal performance in the public sector

It goes without saying that thermal performance is essential in public sector buildings. In schools, for example, students need to feel comfortable in order to concentrate, whether they are in small classrooms or large theatres. Likewise, teaching and support staff need optimum conditions to deliver the best education possible.

In hospitals, thermal comfort and consistency is arguably even more important as buildings must support and promote recovery for patients. For example, a 2008 paper explored the effects of temperature and thermal comfort on recovery for patients shortly before and after an operation, which concluded that imperfect conditions could result in a longer recovery period for patients and an increased risk of infections.

While we recognise the necessity of these changes to ADL, it is also important to highlight that this may place a greater burden on contractors that must then be factored into project timescales. However, corners cannot be cut when it comes to meeting the performance requirements of the public sector, and the forthcoming updates to ADL should help to improve the build quality.

Continuity for compliance

To deliver designed performance, reduce heat loss and improve energy efficiency, continuity of insulation is critical. The first step in achieving this designed performance is to be certain that insulation is fitted contiguously and without gaps.

Stone-wool insulation makes this process easier as it is highly pliable so can be closely friction-fitted to frames, without the need for impractical levels of precision cutting. This simplicity minimises the margin for error, supporting reliable and effective thermal performance that reduces thermal bridging.

This process also applies to abutments between insulation boards, another area that can be prone to thermal leakage. The composition of stone-wool insulation allows individual slabs to knit together to create a seamless fit and the workable nature of stone-wool insulation supports the delivery of designed U-values. When using a range of stone-wool insulation solutions, a continuous fit can be achieved across the whole building envelope while also meeting wider acoustic and fire safety requirements.

Building to last

While photographic evidence of installation might help with this process in part, what can’t be accounted for is how insulation will age over the life of a building.

The proposed changes to Part L encourage a greater focus on designed versus as-built performance in the immediate term, but if buildings are to maintain long-term energy efficiency, then designers should consider the ongoing performance of building materials too and especially with insulation.

To achieve this, dimensional stability is key. Buildings can naturally expand and contract over time which can lead to the formation of gaps and voids. Stone wool maintains its shape and properties over time across a wide range of temperatures, and has the resilience to accommodate building movement when fitted under compression. It has a proven ability to provide consistent performance – shown by tests even after 55 years in use – without a drop in its thermal properties.

While ADL 2022 is a step in the right direction, it does not go far enough in ensuring that buildings perform to design standard. Instead, specifiers and contractors should be raising the stakes, selecting durable insulation solutions that make robust installation easier and maintain performance longer term. By doing this, we can provide better performing buildings for future generations and minimise our environmental impact.