Where does recycled material sit in the conversation of ‘the future of construction’? Nick Haughton, Head of ESG at Sapphire Balconies, looks at how ‘next-generation’ manufacturing means companies taking responsibility for not just their carbon output but also the sources of the materials they use. Whilst design flexibility may be raised as a reason not to use recycled materials, the question needs to be raised, does recycled material come at the cost of design flexibility?

Sapphire Balconies

Recycled material

The use of aluminium has played a significant role in companies striving towards more sustainable and innovative climate solutions, and is proven to be remarkably useful to construction industries and customers alike. Recycled material should not be underestimated when it comes to sustainability. Its durability and availability in different grades (or purities) makes it an incredibly versatile material to work with.

However, with industry attention often placed firmly on sustainable economies, how do recycled materials, such as aluminium, stack up?

Aluminium extrusion

All forms of manipulating materials for light, heat or movement require energy, often sourced from unsustainable fuels like oil, natural gas or coal. This results in harmful emissions, which is why sustainability has been a major focus over the last 15 years, urging industries to shift away from fossil fuels and adopt greener energy sources like wind, solar and hydropower to curb emissions.

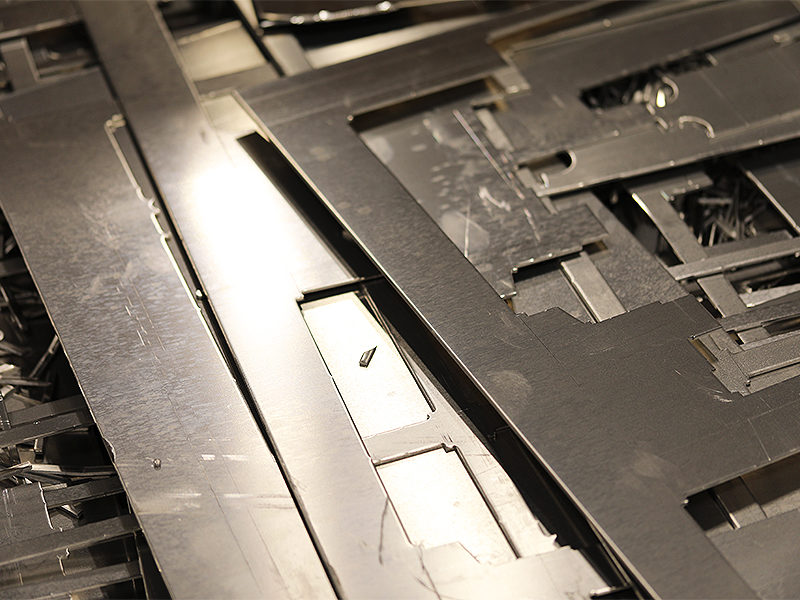

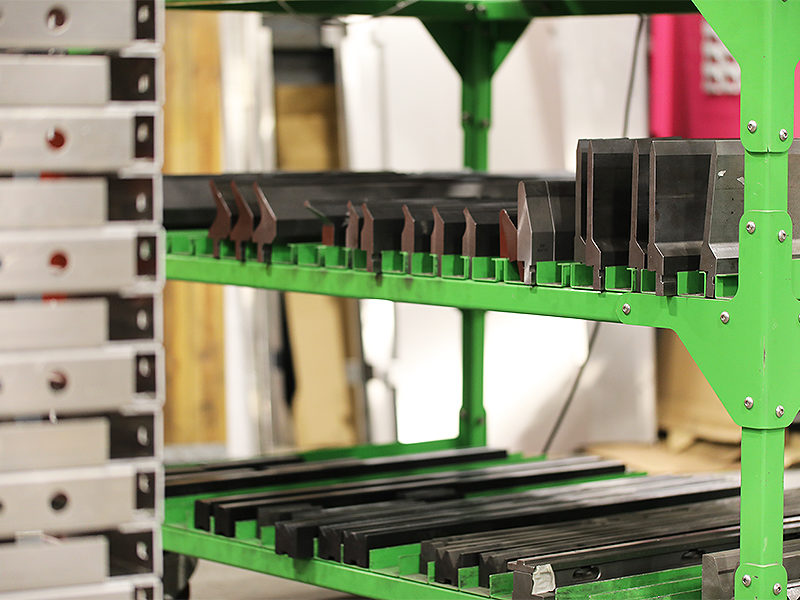

Aluminium extrusion, a process of refining aluminium shapes, has gained traction in product design and manufacturing thanks to its ability to simplify construction. With the ability to extrude aluminium into various strength grades with up to 70% recyclability, it demonstrates a strong strength-to-weight ratio. This process, combined with different aluminium grades, allows for customisable shapes and thicknesses of components, reducing carbon emissions impact by up to 44% through intelligent use of material and reduced material wastage.

ESG explained

Given that many companies globally are adopting an ESG framework, it’s crucial to understand exactly why ESG is important from a sustainability perspective. ESG goes beyond simple carbon-cutting measures and incorporates environmental, social and governance strategies into a business at a fundamental level.

Recycled content contributes to the ‘environmental’ pillar of ESG. By reducing the amount of extruded aluminium a company produces, energy consumption and waste generation can further be reduced as a by-product.

How valuable is recycled material if you can’t prove it’s recycled?

Reaching net-zero carbon emissions is an absolute for a company aiming for sustainable practices, but carbon credits and greenwashing aren’t the way to go about it. To strive for true sustainability, you need to prove that your material is recycled and provide a form of traceability to show the source of the material.

Attempting to find the source of all materials can be strenuous and so many companies opt to buy carbon credits in an attempt to offset their carbon emissions. However, this is not true sustainability as these credits simply ‘allow’ a company to avoid what they might see as an inconvenience. For true sustainability, either traced recycled materials must be used or other methods of reducing carbon emissions must be considered, such as reducing levels of transport, reducing the amount of material in your product or making sure your waste products are recycled properly.

The limitations of recycled material

Global demand for aluminium profiles and the means to extrude them has remained strong into late 2023. Considering the enduring influence of the coronavirus pandemic, the ongoing conflict in Ukraine and the continuing impact of Brexit, increased global demand is still an issue and has forced many countries to increase production, leading to scarcity of supply.

Limiting your opportunities by focusing too heavily on achieving a highly-recycled material can be a hurdle for many buyers of extruded aluminium. The importance of recycled content should lie in the weight of CO2 per item, not the percentage of recycled content in the materials themselves. Reducing the total emissions in a product is far more sustainable than increasing the percentage of recycled content used, as the less embodied carbon used by weight will directly impact how sustainable a product can be.

There are no hard and fast rules on what you should or should not do when it comes to the materials you use, but by staying informed on the role of recycled material, we can all make more informed and more viable choices. Adopting a well-thought-through ESG strategy can make a great difference to your approach to sustainability.

Removing aesthetic limitations

Most recycled materials can easily be customised to meet specific design requirements. This flexibility enables architects and builders to tailor the appearance of construction elements to match the desired aesthetic of a project.

Aluminium, for example, is an incredibly malleable construction material to begin with, but by using recycled aluminium, custom extrusions can be formed without extra waste from an ore extrusion. In this instance, aesthetics actually come as a benefit when using recycled material.

Is recycled content the future of construction?

Recycled content holds a great deal of potential for the future of the construction industry. Through a massive impact on sustainability, resource conservation and aesthetic possibilities, recycled material can reduce a project’s carbon footprint and alleviate the burden on finite resources.

A paradigm shift appears to be incoming – with a laser focus on ESG strategies in the lead up to 2030 and beyond, companies will likely begin to embrace recycled content not just as a carbon-saving measure, but also as a commitment of responsibility for construction for generations to come.

Conclusion

No, sustainability does not need to come at the cost of design flexibility. Thanks to recycled content’s malleability and flexibility, architects and developers are provided with the ability to tailor construction elements to meet specific aesthetic preferences. Whilst there are still limitations with recycled content, such as global demand and scarcity of supply, the benefits largely outweigh the detractors.

Sapphire’s Next Generation suite of balconies, as well as their further range of products, use recycled materials to maintain a level of sustainable manufacturing throughout the entire process. There are no hard and fast rules on what you should or should not do when it comes to the materials you use, but by staying informed on the role of recycled material, we can all make more informed and more viable choices. Adopting a well-thought-through ESG strategy can make a great difference to your approach to sustainability, and Sapphire are proud to have published their ESG strategy earlier this year.

Recycled content is likely to be a pivotal force in shaping tomorrow’s construction landscape, benefitting resource conservation, sustainability and the industry’s commitment to responsible construction practices for now and the future yet to come.