Faced with the challenge of balancing busy work schedules and tightly squeezed budgets, installers, specifiers and building engineers can often find themselves sticking with the products and materials they have known for years and have come to trust.

Geberit

But what if there is a better solution? What if a reluctance to change products and materials is preventing enhanced acoustic performance, cost savings and installation efficiencies from being achieved?

Greg Austin, Assistant Product Manager at Geberit, discusses the five key materials used for drainage pipes and fittings, and how they can help installers specifying for projects with acoustic requirements.

Effective drainage specification

Each material comes with its advantages and disadvantages, especially when considered for specific applications, but before the merits of five specific materials are explored, it is important for the merchant to consider the demands of drainage pipes – and how this will impact an installer’s purchase.

There are the obvious considerations, like acoustic performance (i.e. how well the pipe can dampen the noise of flushing water or waste as it passes through), lifespan of the pipe and cost, which encompasses both the material cost and installation cost. We must also consider the smoothness of the pipe bore and how well it allows water to flow and, therefore, avoids blockages. For metallic pipes, we must factor in susceptibility to corrosion, including whether any coatings are required.

Installation technique is also a critical deciding factor for installers. Depending on the material choice, piping systems can be installed in several ways. Mechanical clamps, push fitting, solvent welding, butt welding or electrofusion welding, are all ways in which pipes can be connected. Notably, each system incorporates different costs and labour requirements.

Now let us examine five material options for soil and waste drainage systems; enhanced polypropylene composite, mineral-reinforced polyethylene, cast-iron, HDPE (high-density polyethylene) and PVC (polyvinyl chloride).

Enhanced polypropylene composite

Enhanced polypropylene composite is relatively new to the UK market, but is the latest demonstration of the UK building products market taking the lead from European product development. Enhanced polypropylene composite is a proven material, used for many years on the continent and now finally delivering benefits to UK specifiers, engineers and installers too.

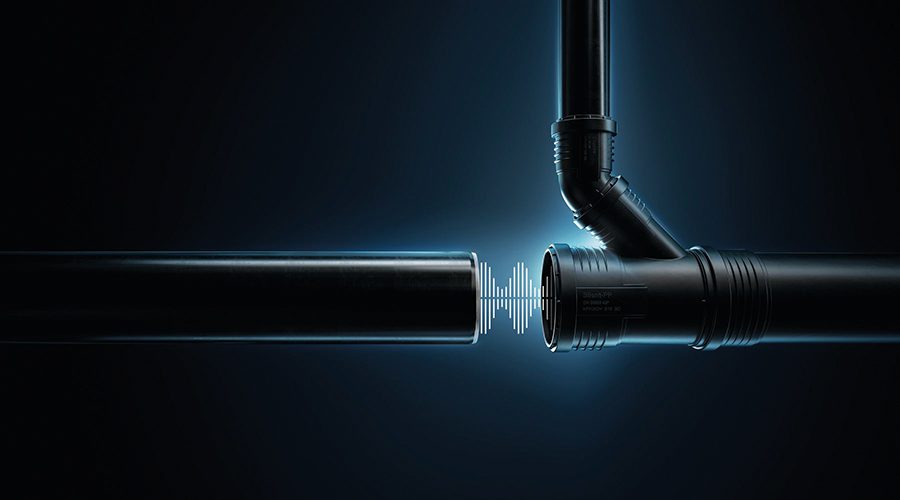

Geberit Silent-PP is made from mineral reinforced polypropylene, improving the physical properties of the material and achieving first-class acoustics optimisation, effectively reducing the natural vibrations and noise.

Another important factor is the installation itself. Enhanced polypropylene composite can be installed using the push-fit installation system – installers

are simply required to push the components together and rotate to realign them, reducing downtime and minimising costs.

Crucially, it is comparative over a project in price to a PVC installation, which makes it a fantastic choice for acoustically sensitive applications. In fact, enhanced polypropylene may even provide an opportunity to deliver overall project cost savings compared to lagged PVC by reducing or removing the need for lagging on some projects.

Cast-iron credentials

In comparison, cast-iron is an alloy of iron and carbon that provides intrinsic acoustic properties, as the material is both dense and thick, preventing air transmission.

However, cast-iron is more expensive to purchase and install when compared with plastic alternatives.

As an iron-based material, it is susceptible to corrosion; whilst modern cast-iron pipes have more advanced coatings, many older buildings are inevitably facing corrosion issues after 40 or 50 years of service from their original drainage systems.

Most significantly, cast-iron pipes are also more likely to build-up depositions than a plastic pipe due to a higher chance of roughness of the pipe bore. Through decades of constant use, the depositions will gradually worsen, leading to serious blockages and clogging, which will eventually cause leaks if left untreated.

A shift towards HDPE

Offering a viable alternative to cast-iron, HDPE is becoming an increasingly popular material for drainage pipes and fittings in commercial buildings.

Although standard HDPE isn’t as dense as other piping materials and lacks enhanced acoustic properties, it does possess lightweight flexibility and installation benefits. The initial investment in HDPE can often be outweighed by reduced maintenance costs and extended system life cycle – not to mention the peace of mind that comes with a strong and reliable welded solution.

HDPE pipes have a smooth bore which is maintained throughout their lifetime, helping to smooth the transition of any waste. Also, the interior of an HDPE pipe can often be cleaned thoroughly simply by flushing the toilet or running the tap.

PVC – the old favourite

Currently, around 75% of soil and waste pipes and fittings sold in the UK are made from PVC, which is incredibly lightweight, cost-effective and easy to install. However, PVC is a relatively thin material and does not possess enhanced sound performance like other plastic alternatives.

PVC is also one of the most environmentally hazardous polymer materials for the content of chlorine which releases hydrogen chloride during thermal recycling – chlorine is chemically bound to carbon in the polymer, but when the structure is broken up during incineration the strongly acidic gas is produced.

Mineral-reinforced HDPE

Wherever it may occur, noisy discharge pipes are irritating – a problem that is easily eliminated with a waste and drainage system comprising mineral-reinforced HDPE.

These pipes and fittings, optimised as they are with respect to sound insulation and hydraulics, are suitable for both discharge stacks and floor connections and ensure quiet and effective drainage in every kind of building. The mineral-reinforced plastic is much denser than its HDPE and PVC counterparts, reducing vibrations and noise.

Be open to innovation

Ultimately, the choice of material for waste drainage pipes and fittings will come down to a number of considerations, but the key takeaway is not to rule out different or new materials when speaking with installers about their project’s drainage requirements.