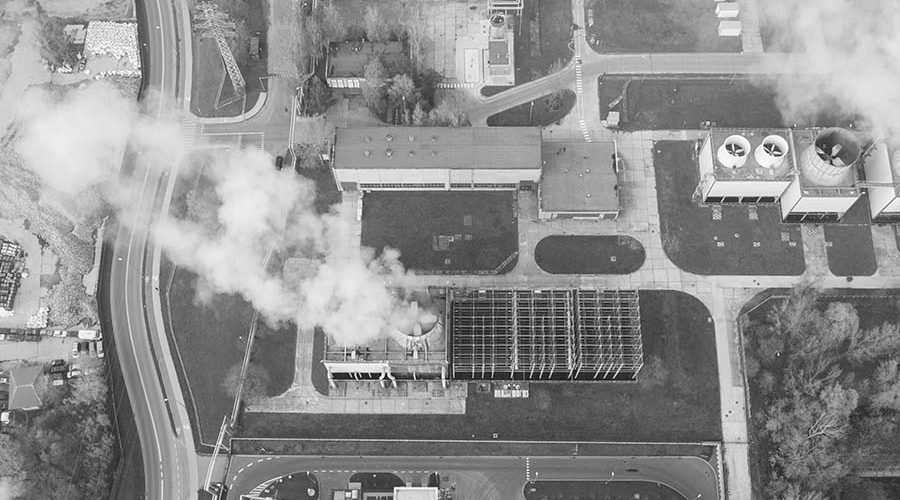

With a Government target in place to reduce greenhouse gas emissions to net-zero by 2050, innovators within the construction sector are exploring ways to reduce the environmental impact of property development and the built environment.

Withers & Rogers

While much of the focus to date has been on energy-saving technologies, innovators in the sector are increasingly turning their attentions to tackling ‘embodied carbon’. Every building material has its own carbon footprint. Embodied carbon refers to the greenhouse gases released throughout the supply chain of a material, including during the extraction of raw materials, as well as the processing, transportation and construction stages. This can account for up to 50% of a building’s whole-life carbon emissions.

Traditionally, the reduction of carbon emissions has focused around increasing energy efficiency and pushing for renewable energy production. However, to sufficiently reduce carbon emissions, the industry must now concentrate on embodied carbon reduction too.

As the issue of climate change escalates, the construction industry is increasingly taking both embodied and operational carbon emissions into account. The UK Green Building Council has an ‘Advancing Net Zero’ campaign, which aims to promote and support the acceleration of net-zero carbon building and provides a framework to support its delivery. So, how can recent innovations help the construction industry in its mission to reduce levels of embodied carbon?

The building materials which hold the greatest carbon footprint are concrete and steel. As such, these have become a target for innovators looking to reduce embodied carbon levels.

Kiss House, a UK home provider, has recently filed a UK patent application for a technology concerning the reduction of embodied carbon in the foundations of buildings. Foundations often largely consist of either steel or concrete, making them a major contributor to embodied carbon levels. Kiss House’s solution involves the use of glass reinforced fibre beams and joists, which rest on small steel screw piles. In comparison to traditional foundation systems, this method lowers their carbon footprint by 70%.

Other innovators have focused on making the production of cement more environmentally-friendly. In January 2020, European research and technological development centre, Tecnalia, had a patent granted for a more energy-efficient method of producing cement clinker, called ‘microwave clinkerisation’ or MIKE. Due to the very high temperature needed to produce clinker from calcium carbonate, and the base material having carbonates within it, a considerable amount of CO2 is emitted during the clinker production process. By changing the composition of the base material, Tecnalia has created a means of forming clinker at lower temperatures, which helps to reduce the embodied carbon of the resulting cement.

Another innovator that has developed a new composition of concrete is the Ronzoni Institute in Italy. The Ronzoni Institute has filed a European patent application, which could ultimately lead to patent protection in the UK, involving a cement composition containing less calcium carbonate. The result of this is that fewer carbon emissions are released into the environment during the manufacturing process.

Collaboration between innovators, both large and small, also looks to be a promising route to reducing embodied carbon emissions. LafargeHolcim, a global building materials and solutions company, has partnered with SME Solidia Technologies to develop a reduced CO2 cement. Using a unique concrete mixture, and a specialised curing process that utilises CO2, they are aiming to create a concrete that has a 70% lower carbon footprint than traditional portland cement systems.

Through collaboration with larger businesses, smaller businesses with a large intellectual property (IP) portfolio can utilise their IP whilst reducing the barriers to bringing a new product to market and gaining access to a larger portion of the market. Thus, collaborations of this type may provide SMEs with the opportunity to promote their business to a wider audience, whilst also facilitating further R&D activity.

When entering into an R&D-focused collaboration, it is vital for the businesses involved to establish each party’s existing IP which is being shared, and to agree on ownership of IP created during the collaborative work. The sharing of any existing IP should be limited to what is strictly needed for the particular project, and should only be shared under the protection of a non-disclosure agreement.

Much is being done to reduce carbon emissions in the construction sector, and the net-zero emissions by 2050 goal is becoming ever more possible with each innovation. In order to achieve this goal, the construction industry will need to continue to innovate to further reduce the embodied carbon in the built environment.

Mark Sugden is a UK and European patent attorney leading the Housing & Construction Group at European intellectual property firm, Withers & Rogers.