Hot water is the primary method of controlling legionella bacteria in water distribution system in public buildings. The old adage is keep it hot and keep it moving. The recent energy crisis has placed extraordinary pressures on budgets. However, reducing the temperature or even stopping hot water production is a false economy that places the public at risk. Carole Armstrong, Marketing Manager at DELABIE, looks at how to keep public washrooms safe for users.

Delabie

Naturally present in water, legionella bacteria develop in standing water with a source of nutrients, such as biofilm in pipes or rusted water storage tanks. They multiply at 20 to 45°C and can be harmful if inhaled in aerosol form, i.e. steam from showers.

Hot water is the typical method for controlling legionella bacteria in non-domestic buildings. Health and safety guidance recommends producing and storing water above 60°C, and distributing it at 50°C (55°C in healthcare). At these temperatures, 90% of the bacteria die within two minutes. Stopping hot water production risks creating a large store of stagnant water. And, if the temperature falls below this guideline, the risk of bacterial growth increases. Maintaining these minimum water temperatures reduces the risk of contamination and is more energy efficient than allowing water to cool during periods of inactivity then reheating.

Complex systems lead to temperature drops and increase the contamination risk. To minimise this risk, pipe runs should be kept to a minimum (ideally <2m). Lagging pipes prevents heat loss and, where cold and hot water pipes run side by side, insulation will stop heat transfer, preventing the cold water temperature rising above 20°C where legionella bacteria are no longer dormant.

Technical solutions in the fight against legionella

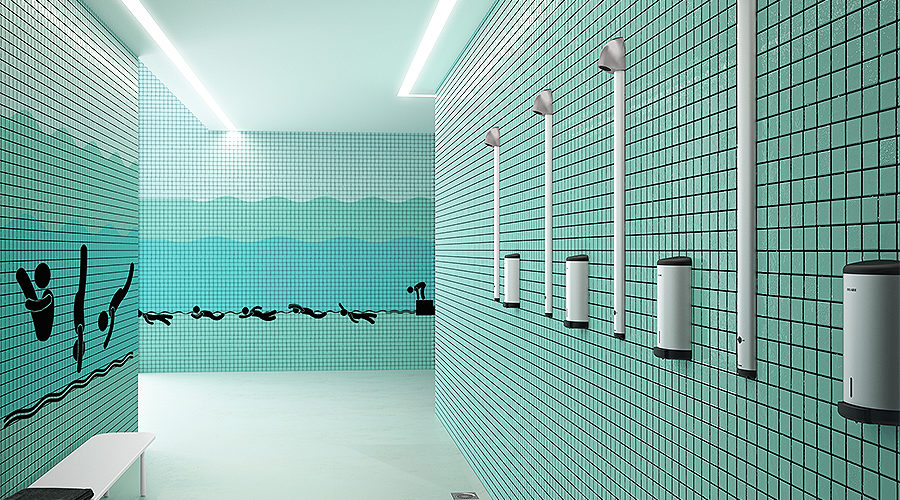

In sports facilities, thermostatic mixing valves (TMVs) are typically used to blend incoming hot water to a safe temperature for showering. Type 3 TMVs have a failsafe to prevent scalding if the cold water supply fails and, conversely, the cold water shuts off if the hot water supply fails. In normal circumstances, the failsafe requires a minimum temperature differential between the incoming water supplies to ensure user safety. In the absence of hot water, the failsafe must be overridden to ensure water is delivered at the outlet.

Water controls featuring a pre-programmed automatic duty flush will prevent stagnation and bacterial development. With DELABIE’s electronic showers, an automatic rinse activates every 24 hours after the last use, running for 60 seconds. The solenoid valve is piston operated, removing the need for a diaphragm, which can trap water and harbour bacteria. Battery-operated taps and showers are easy to install and they flush the pipework automatically to prevent stagnation. Touch-free electronic controls are also more hygienic, preventing the spread of germs by hand.

Water-efficient solutions

Self-closing mechanical or electronic taps and showers can optimise water usage. The valve closes automatically after seven seconds for self-closing taps, and 30 seconds for showers; or after removing hands from the detection zone (sensor-controlled models). A pre-set flow rate of 3l/minute for taps (6l/minute for showers) will prevent unnecessary waste. The user can, therefore, wet their hands, apply the soap or shampoo, and rinse without the water running continuously. With a DELABIE electronic tap, water consumption drops to 0.6 litres per use, a decrease of almost 90%. And reducing water consumption reduces the amount of energy required to heat it.

Reducing energy costs can be achieved without compromising user safety. Legionella prevention measures must be maintained but by reducing unnecessary water consumption, both water and energy bills can be managed in public washrooms. By understanding the risks and installing products specifically designed to meet these challenges, the risk of contamination and scalding can be managed without blowing the budget.

Temperature / Legionella development:

—

< 20°C / Dormant

24-45°C / Multiplies

50°C / 90% die within two hours

60°C / 90% die within two minutes