By connecting graphical and non-graphical product data, through people and technology, with key challenges, building information modelling (BIM) is streamlining design and construction processes – from the manufacture and assembly of packaged single products such as pressurisation and booster sets to systems of products and processes such as entire treatment plants, writes Jamie Mills, Xylem’s Global BIM Manager.

Xylem Water Solutions UK

The implementation of BIM starts by defining key business, regulatory, customer and project requirements which then define the outcomes of the asset information model. This structured set of information is developed using a project information model which provides a single source of truth, allowing better-informed decision-making. Analysis of the data reduces wastage and risk whilst allowing engineers to optimise space and performance, reduce carbon footprint, energy consumption and increase operational effectiveness; reducing life cycle costs from the very inception of a project, right through to operation.

In this light, it is clear to see why some prefer to call BIM ‘better information management’. With its ability to simplify and democratise the exchange of digital information, it allows organisations to make more intelligent use of data, streamline the construction process, eliminate legal disputes over delivery requirements, and significantly increase return on investment.

Its role in the construction industry, including the water sector, is only set to grow as the trend towards digital transformation accelerates. In 2019, Xylem asked planners worldwide about the importance of BIM for their current business, and 91% said it was mandatory.

In the UK, Norway, Denmark, and Finland BIM is already required in the design and construction of public buildings and infrastructure, and Germany, Italy, France, Spain and the Netherlands are about to follow suit.

Mapping digital twins

BIM is far from being a 3D modelling technique. It is a structured way of working in a digital environment to collect, manage and exchange information throughout an asset’s lifecycle, whether that’s a commercial building, an industrial factory, or a water utility facility.

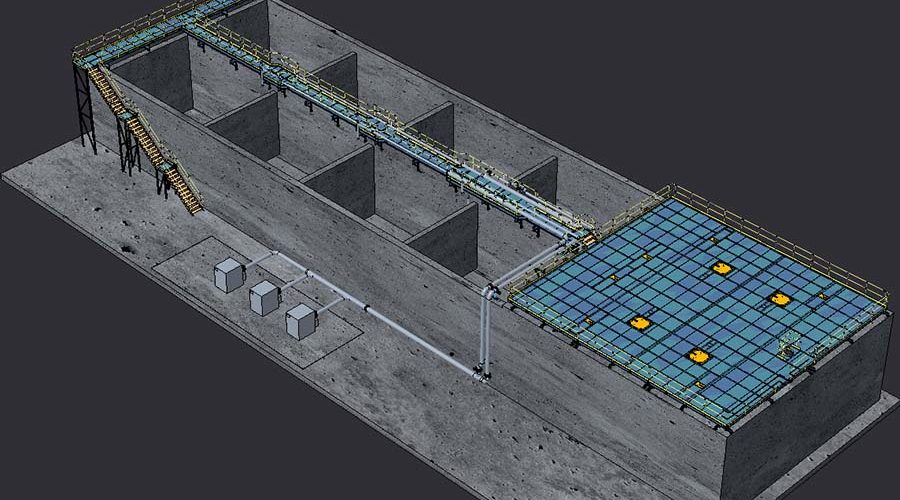

Graphical and non-graphical data from single asset components and processes are mapped to create digital asset models, which can go on to support digital twins “a digital representation of built assets construction within a natural environment and live links to performance of its systems, processes and functions”.

It means that project teams can interrogate the digital twin of a treatment works and its processes, for instance, to ensure critical information gets to the right person, at the right time, at the right level of detail.

A team member who needs information on the location or performance of products, whether that be manufacturer details, water quality, or maintenance procedures, can access it quickly and seamlessly via the digital twin.

This concept of storing reliable information about an asset’s performance and construction allows personnel to make faster, more accurate decisions that lead to more efficient, cost-effective, and safer planning and operation of the process.

Additionally, the monitoring of process performance metrics and asset health, combined with structured, planned preventative maintenance schedules, reduces downtime and slashes risks, such as pollution.

Case study: Connecting the data

Collectively, this efficient use of data frees up resources and enables owner-operators to optimise processes and make more informed investments.

This was demonstrated during a BIM-enabled build for United Utilities UK, Blackburn STW.

The contractor, Laing O’Rourke, connected Xylect, Xylem’s product selection tool, to the project’s information model and product data exchange processes.

It created a collaborative environment that allowed project design engineers to share information with Xylem’s application engineers and the tendering team in real-time, meaning they could all work together towards the optimum solution.

Through this process, Xylect was able to quickly identify the need for Xylem Flygt pumps within the detailed design, and share the product’s engineering data, including construction objects and data sheets, directly with the contractor.

Laing O’Rourke engineers then embedded a direct link into the Navisworks federated model interface, connecting the Flygt 3D object with the relevant non-graphical product data from Xylem’s back-end systems. Engineers were then able to access product data directly – whether they needed to view it on mobile devices out in the field or pull it in from the asset information model.

This approach creates a single source of truth that ensures product data and associated documentation, such as installation operation and maintenance documents, part lists and technical performance data, are related to the correct asset.

The time- and resource-saving value of this within the context of expensive and complex water system design cannot be underestimated. The simple act of sharing data meant engineers were able to make more informed, rapid, and confident decisions throughout the design stage, while avoiding the time-consuming exchange of emails, and lags between documentation being requested, sent and received.

By connecting 3D objects to their product data via an embedded link, the team slashed the risk of operator confusion and eliminated the need to search for documents and data.

Not only did this provide efficiencies while developing the information model, but it will also streamline processes going forward – this robust connection will inform better decision-making around assets operation, maintenance and process performance optimisation. Ultimately, this will reduce the total lifecycle cost of the asset.

BIM: Coming of age?

By taking traditional 3D modelling and infusing it with the power of data, utilities and public sector water providers, as well as architects, building planners/specifiers, can streamline processes, optimise workflows, and secure the future of their projects.

The benefits are in no doubt, but, with utilisation varying by country and sector, we are only at the beginning of the BIM story. Given the trend towards digitalisation, which has been accelerated by the advent of COVID-19, we could be about to see the wide-scale standard adoption to digital twinning and all the advantages it entails.